Palladium recovery

![]() AJINOMOTO OMNICHEM

AJINOMOTO OMNICHEM

Main features:

- Palladium recovery

- Water and solvent purification

- Circular business case

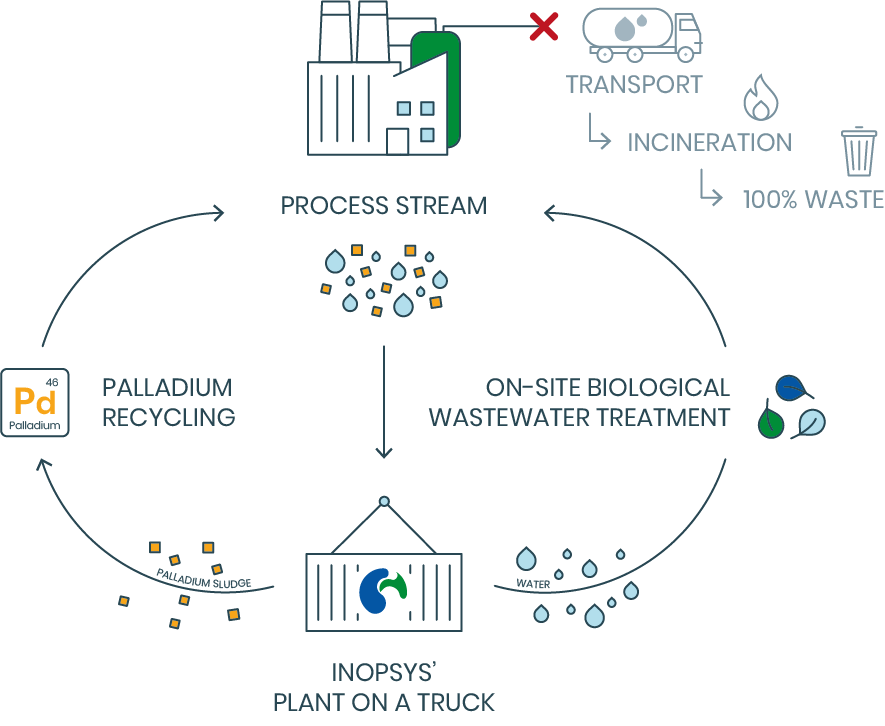

A leading client in the chemical industry relies on palladium (Pd) as a catalyst in their production processes. Given the high cost and limited availability of Pd, the company sought a solution to recover and reuse this catalyst, aiming to reduce waste, improve resource efficiency, and move towards more sustainable operations.

Inopsys developed a modular, end-of-pipe recovery system tailored to the client’s aqueous waste stream.

The system operates in two sequential stages:

- pH adjustment through CO₂ injection: The first module prepares the waste stream for metal recovery by injecting biogenic CO₂, adjusting the pH to optimize palladium capture.

- adsorption through Ion Exchange (IEX): The second module utilizes advanced ion exchange resins to extract palladium from the side stream. This targeted extraction process is both selective and efficient.

Since the initial deployment, technological upgrades were implemented, allowing the mobile unit to use more advanced resins, further increasing efficiency and recovery rates. The entire setup remains compact, mobile, and adaptable to evolving process requirements.

The system enables successful palladium recovery, supporting the client's transition to a circular business model. It reduces operational costs, minimizes destructive waste handling, and promotes sustainable resource use.

The unit is ATEX certified, meeting stringent safety requirements.

.png)