Specific API Removal - Steroid

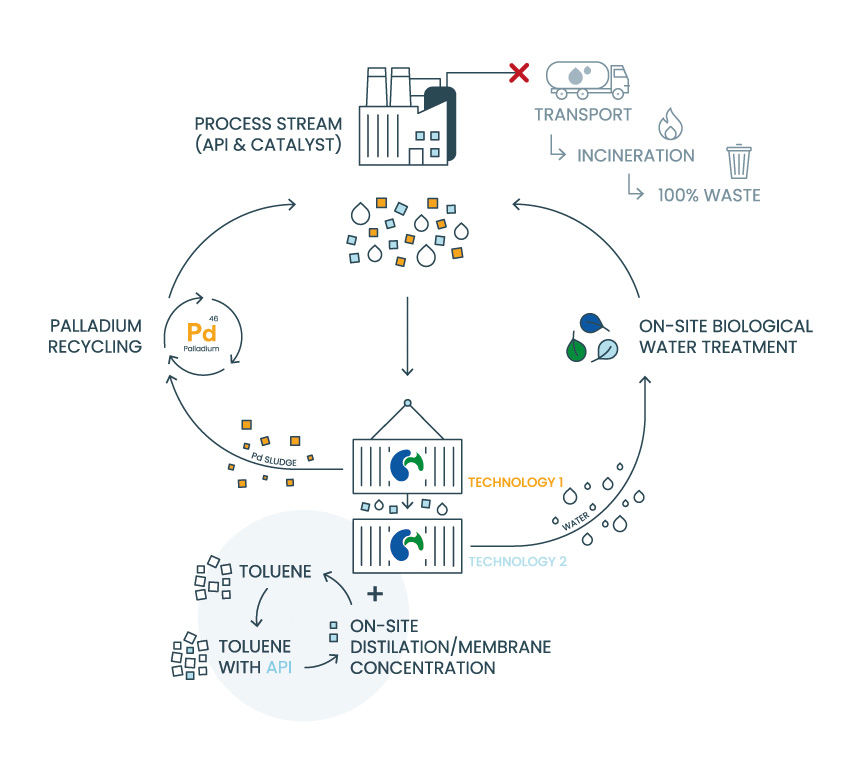

At a pharmaceutical production site of active pharmaceutical ingredients (APIs), a highly potent hormone used in cancer treatment posed a serious challenge for treatment of a wastewater stream. The presence of this steroidal API made the stream unsuitable for on-site treatment, requiring incineration for disposal – a costly process with significant environmental impact.

Inopsys installed a mobile and modular solution tailored to the complexity and sensitivity of the waste stream. The system featured a two-step treatment process:

1. Membrane filtration: separating solid particles and enabling the recovery of the valuable palladium (Pd) catalyst.

2. Solvent extraction: carefully selected for its effectiveness in removing, rather than destroying, the high-potency steroidal API to prevent the release of even trace levels of active compounds, ensuring safety and precision.

The implementation of the mobile unit leads to the successful removal of the steroidal API, making the treated wastewater safe for discharge to the site's conventional biological treatment plant. Additionally, the palladium catalyst is effectively recovered. The process also enables on-site recovery of the solvent.

Transformation of a linear process into a circular system

This innovative solution has been operational since 2021 and was specifically designed for a dedicated waste stream at the client’s site. Housed in a mobile, ATEX-compliant unit, it offers a safe and flexible setup that’s easy to relocate if needed.

our unit is mobile and modular.

- No on-site assembly - safety

- Easy to move

- No real infrastructure adaptation or big CAPEX required

- Changes to the side stream composition, production, of regulations can be handled with replacement or addition of new module(s)