A tank storage facility needed to remove PFAS from precipitation water (50 m³/h) before discharge to an industrial WWTP. The contamination resulted from historical fire-fighting foam use and was compounded by high COD levels from stored organic materials.

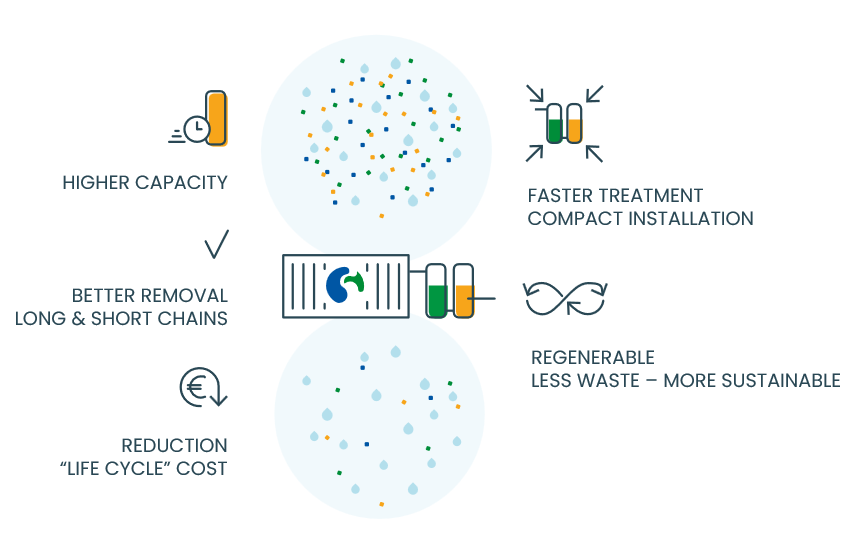

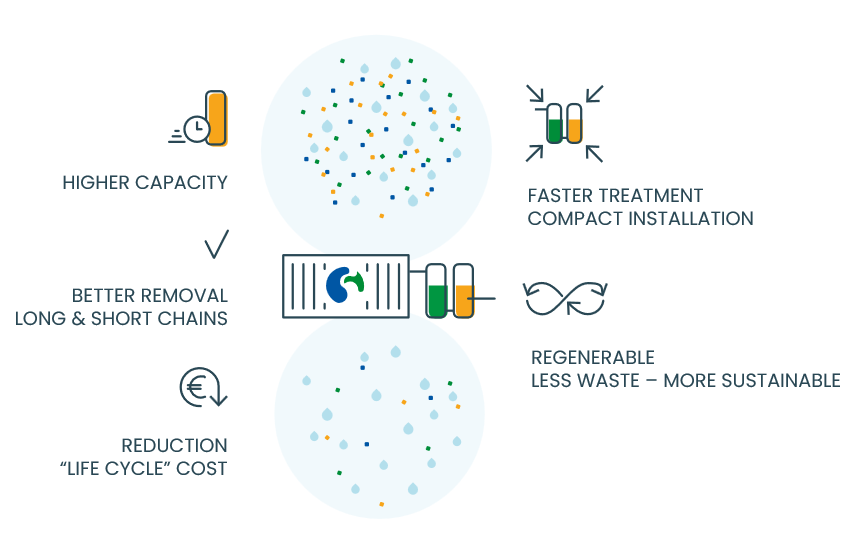

InOpSys conducted lab trials to design a fit-for-purpose treatment train, focusing on TSS removal followed by PFAS-specific ion-exchange (IEX) resins.

Given the elevated COD, IEX was selected over granular activated carbon (GAC) for better PFAS selectivity and cost efficiency, while organics were left for downstream WWTP treatment.

Since November 2025, InOpSys’ fully automated unit has been reliably removing all PFAS, providing a cost-effective and sustainable solution for industrial water management.