Zinc recuperation

![]() JANSSEN PHARMACEUTICA

JANSSEN PHARMACEUTICA

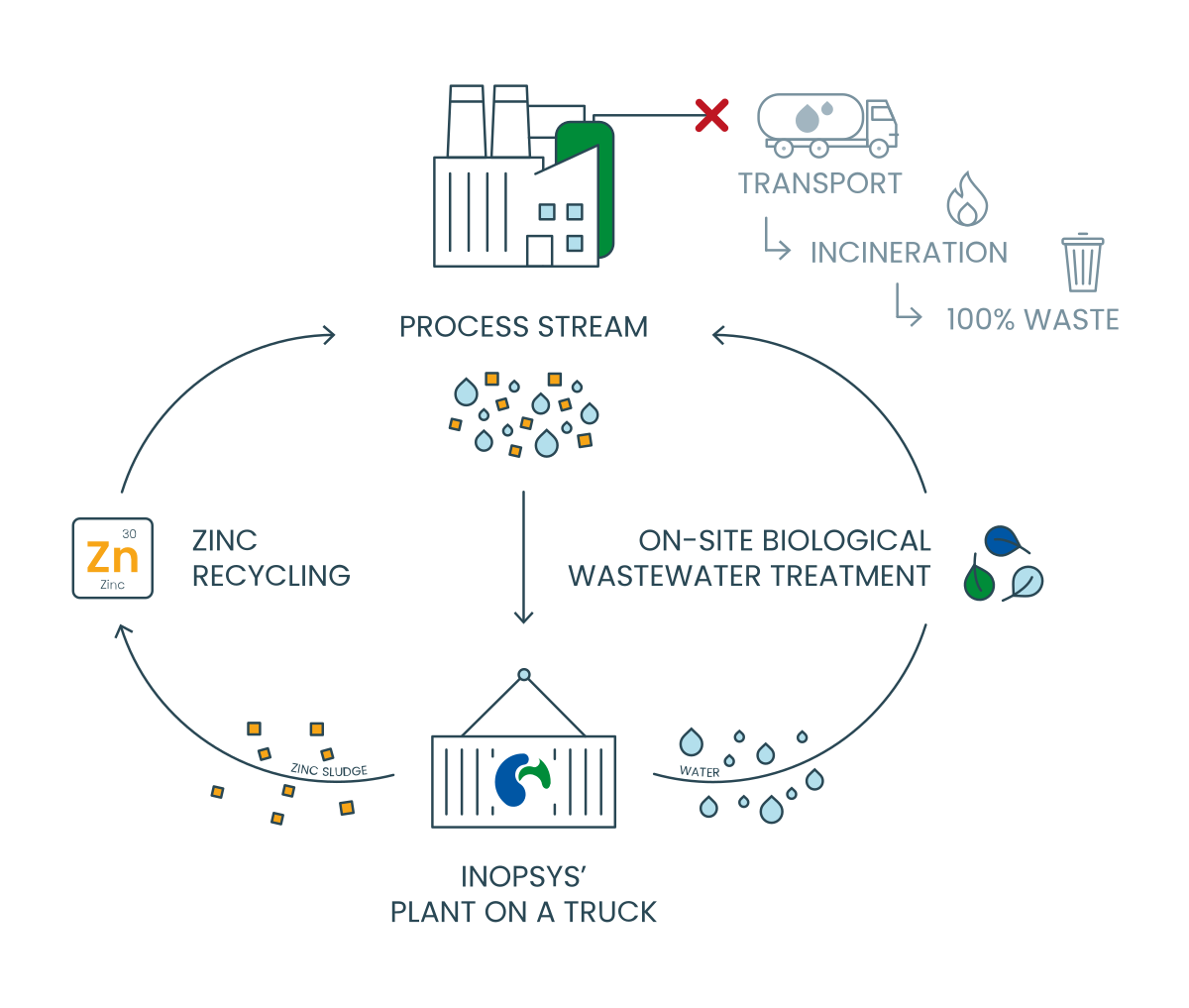

A major pharmaceutical production plant relies on zinc (Zn) as a catalyst in its processes. However, the resulting wastewater stream contained high concentrations of zinc salts, rendering it too toxic to be treated by the on-site industrial wastewater treatment plant. As a result, the contaminated water had to be transported offsite for costly and less sustainable incineration.

Inopsys provided a sustainable alternative by installing a mobile and modular treatment unit at the production site. This innovative system is designed to precipitate zinc from the wastewater stream as zinc sulfide (ZnS), significantly reducing the toxicity of the effluent.

This solution not only enables the safe on-site biological treatment of wastewater - eliminating the need for off-site incineration - but also facilitates the recovery of zinc, which Nyrstar reuses as a raw material in its zinc production process. This approach establishes a circular business model, both within the pharmaceutical company and through its external collaboration.

A Circular Success Story

Since going live in 2017, this solution has recovered over 50 tons of zinc, significantly reducing waste and supporting resource circularity. It has also contributed to cutting CO₂ emissions by 1 ton for every ton of treated water, according to calculations by CO2 Logic. Recognized for its environmental and circular impact, the project won the Belgian Business Award for the Environment in 2018.