metal removal & recovery.

Inopsys recycles precious metals from liquids. A large part of these liquids originates from reactions based on homogeneous precious metal catalysts, used in pharmaceutical and (fine) chemical industry. We have developed multiple on-site solutions for the recovery of different metals: Pd, Pt, Zn, V, … out of aqueous and pure solvent (side)streams. At Inopsys we believe circular chemistry can save the world.

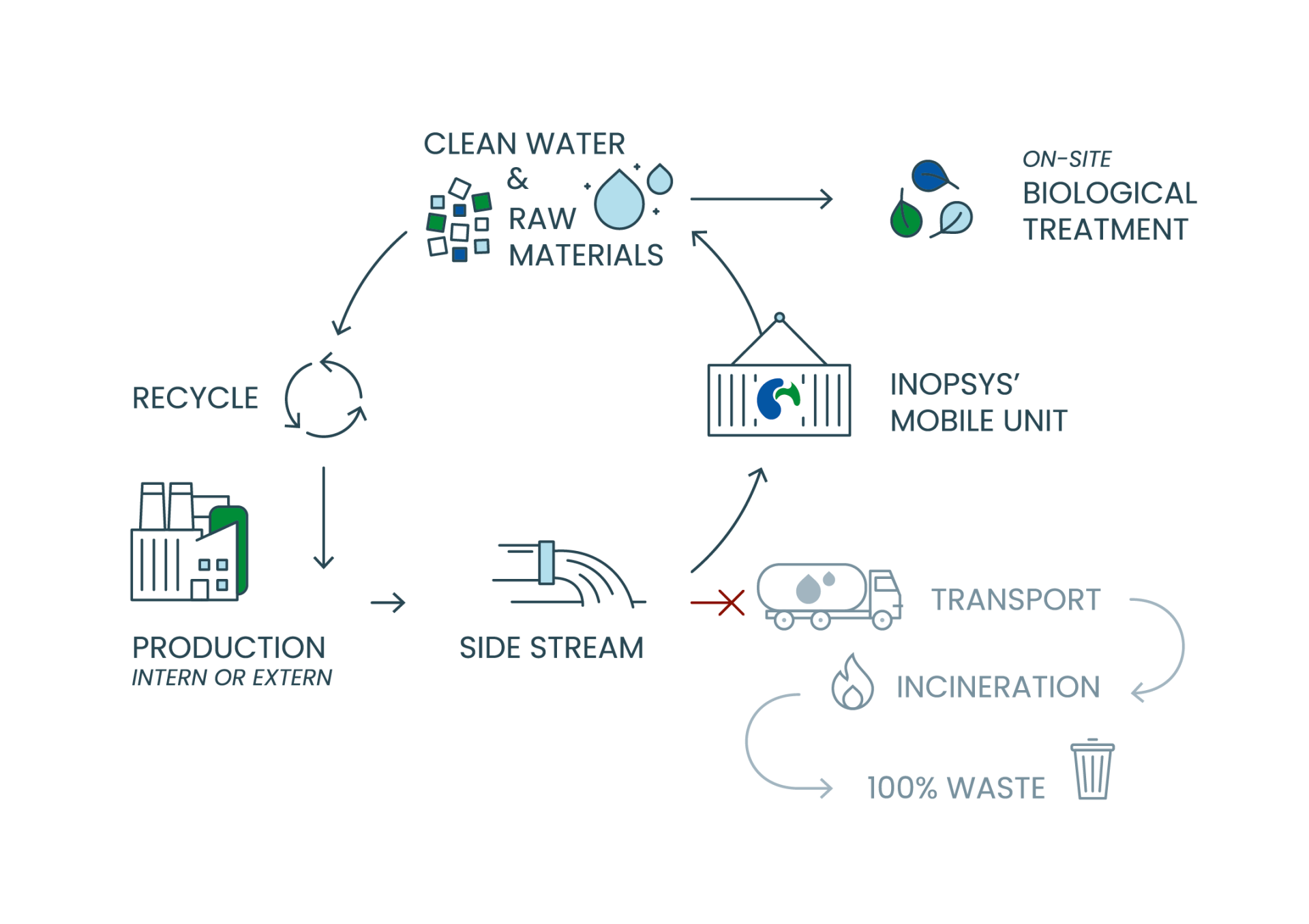

Our solution avoids transport and incineration of the metal containing side stream. This results in no handling and reduced CO2 footprint for our customers. Metals are recovered, refined, and reused as catalyst. Value is created and costs are reduced. Our units are modular and mobile. We provide the solution CAPEX free and via a full DBFOM model.